Bucket elevator includes belt bucket elevator, Ring chain bucket elevator and NE plate chain bucket elevator.Which one should be chosen?

TC Machinery tells you:

1, the shape of the material: material is powder or granular or small block.

2, the physical properties of materials: materials have adsorption or viscosity, or water.

3, the proportion of the material: General bucket elevator parameters are based on the calculation of the bulk density of materials and design of below 1.6, the calculation is too large proportion of the material needed for traction and drive part tensile strength.

4, the transport volume of per unit time.

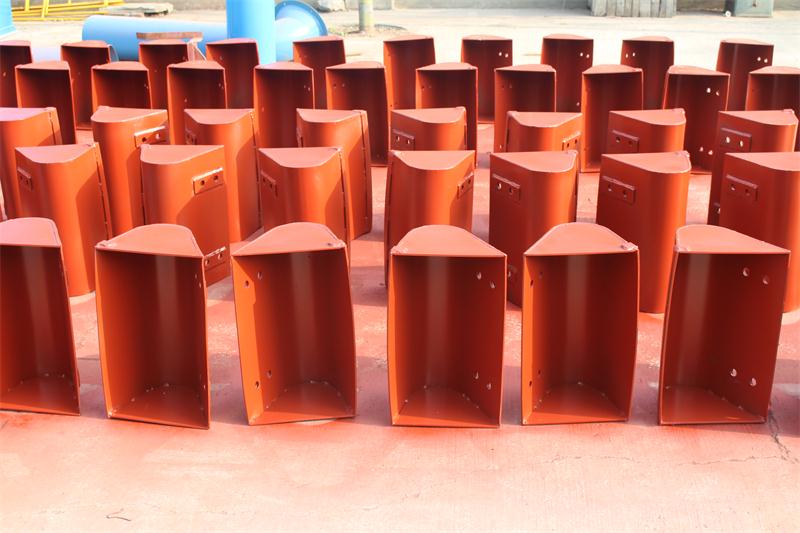

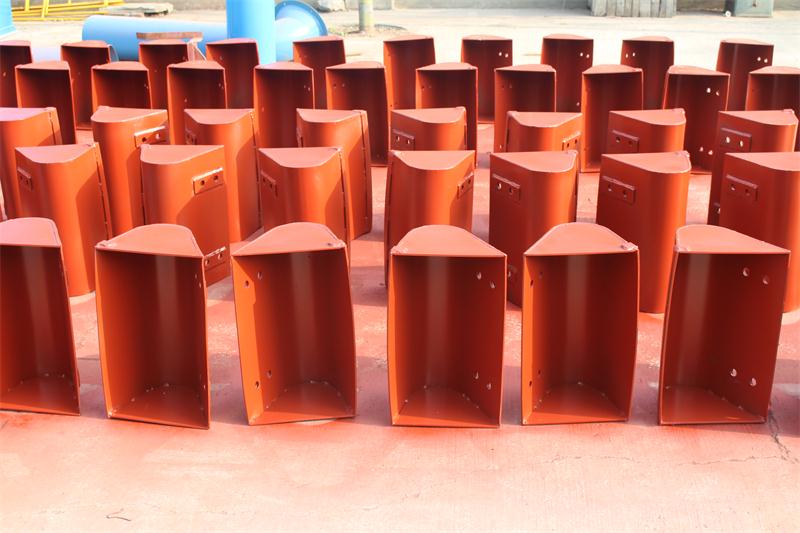

In general, shape of the material directly determines unloading mode of the material,the general rule for the powder material uses centrifugal ejection unloading ,bulk material uses gravity discharge,the difference of unloading mode is decided the using hopper model difference in bucket elevator,centrifugal ejection unloading by shallow bucket and arc bucket, and gravity discharge requires the use of deep bucket.the using hopper model of Bucket elevator is different, in unit time of materials to transport volume is not the same. The bucket elevator to the final delivery depends on the type of hopper, the speed of the bucket, the proportion of materials, material properties, a comprehensive parameter number of hopper.

The specific selection process is as follows: the proportion of materials →driving mode (bucket model)→ material properties→unloading mode→hopper form→the lifting capacity of the series of bucket elevator→determine the model.

TC Machinery tells you:

1, the shape of the material: material is powder or granular or small block.

2, the physical properties of materials: materials have adsorption or viscosity, or water.

3, the proportion of the material: General bucket elevator parameters are based on the calculation of the bulk density of materials and design of below 1.6, the calculation is too large proportion of the material needed for traction and drive part tensile strength.

4, the transport volume of per unit time.

In general, shape of the material directly determines unloading mode of the material,the general rule for the powder material uses centrifugal ejection unloading ,bulk material uses gravity discharge,the difference of unloading mode is decided the using hopper model difference in bucket elevator,centrifugal ejection unloading by shallow bucket and arc bucket, and gravity discharge requires the use of deep bucket.the using hopper model of Bucket elevator is different, in unit time of materials to transport volume is not the same. The bucket elevator to the final delivery depends on the type of hopper, the speed of the bucket, the proportion of materials, material properties, a comprehensive parameter number of hopper.

The specific selection process is as follows: the proportion of materials →driving mode (bucket model)→ material properties→unloading mode→hopper form→the lifting capacity of the series of bucket elevator→determine the model.