Introduction

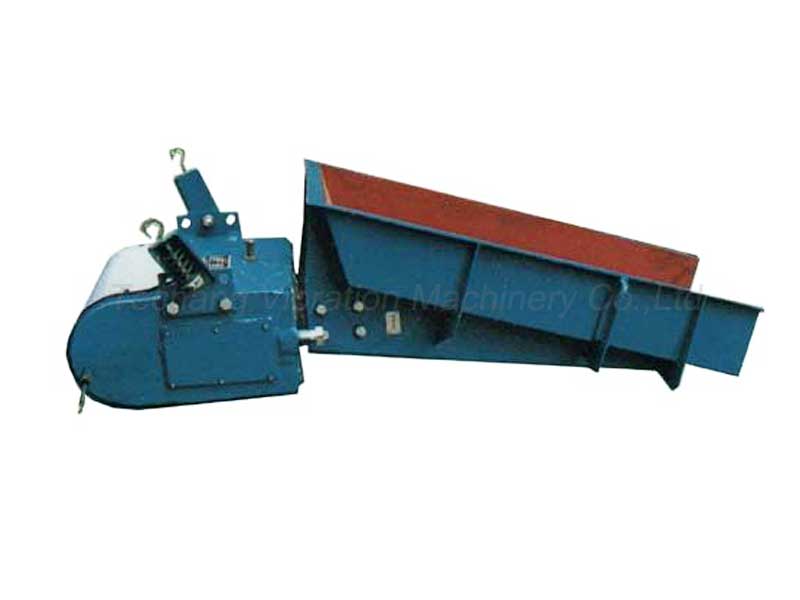

GZ magnetic vibration-actuated feeder is used to feed lump, grain and powder materials to receiving device from storage bin or hopper at a continuous and even flow or quantitatively. For example, it feeds to belt conveyor, bucket elevator, screening equipment, etc.; feeds to crusher, pulverizer, etc., and it is used for automatic dosing, quantitative packaging, etc., and it is also can be used for processes of automatic control, realizing automation of flow operation.

Characteristics

(1) Small volume, light weight, simple structure, easy installation, non-lubricating for no rotating parts, easy maintenance, low operating cost.

(2) The double mass of magnetic vibration-actuated feeder has small electricity consumption under low critical resonance state due to application of resonance principle of mechanical vibration.

(3) Because it can change and open/close material flow instantaneously, so feeding capacity has high accuracy.

(4) The control equipment of GZ magnetic vibration-actuated feeder can easily adjust the feeding capacity during use, and can realize centralized control and automatic control of production process.

(5) Because the material in feed trough is thrown up continuously during feeding, and jumps in the trajectory of parabolic, so feed trough is worn lightly.

(6) The GZ magnetic vibration-actuated feeder will not be used in an environment with explosion protection requirement.

Application

The GZ magnetic vibration-actuated feeder is widely used in mining, metallurgy, coal, building material, light industry, machinery industry and agriculture. It is also applied to automatic dosing, quantitative packaging and production process automation system.

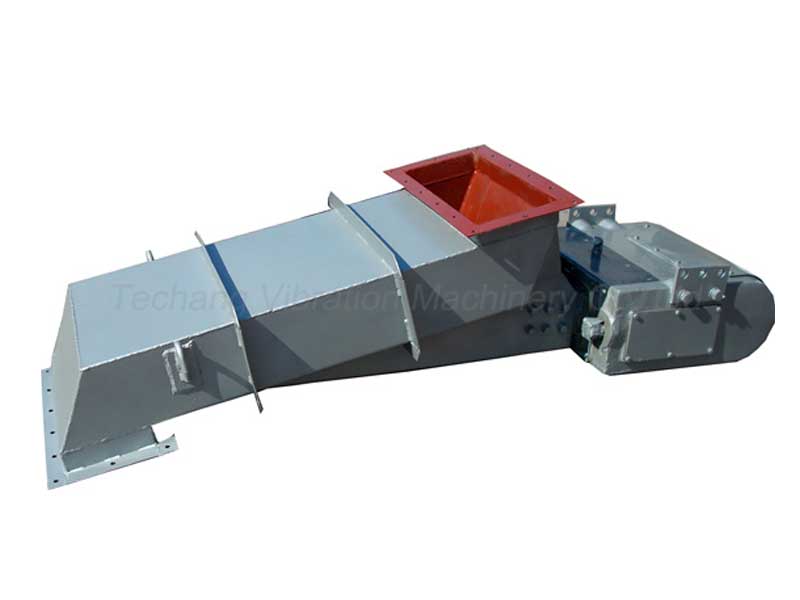

GZ magnetic vibration-actuated feeder is used to feed lump, grain and powder materials to receiving device from storage bin or hopper at a continuous and even flow or quantitatively. For example, it feeds to belt conveyor, bucket elevator, screening equipment, etc.; feeds to crusher, pulverizer, etc., and it is used for automatic dosing, quantitative packaging, etc., and it is also can be used for processes of automatic control, realizing automation of flow operation.

Characteristics

(1) Small volume, light weight, simple structure, easy installation, non-lubricating for no rotating parts, easy maintenance, low operating cost.

(2) The double mass of magnetic vibration-actuated feeder has small electricity consumption under low critical resonance state due to application of resonance principle of mechanical vibration.

(3) Because it can change and open/close material flow instantaneously, so feeding capacity has high accuracy.

(4) The control equipment of GZ magnetic vibration-actuated feeder can easily adjust the feeding capacity during use, and can realize centralized control and automatic control of production process.

(5) Because the material in feed trough is thrown up continuously during feeding, and jumps in the trajectory of parabolic, so feed trough is worn lightly.

(6) The GZ magnetic vibration-actuated feeder will not be used in an environment with explosion protection requirement.

Application

The GZ magnetic vibration-actuated feeder is widely used in mining, metallurgy, coal, building material, light industry, machinery industry and agriculture. It is also applied to automatic dosing, quantitative packaging and production process automation system.

| Model | capacity (t/h) | Granularity (mm) | Double Amplitude(mm) | service voltage (V) | electricity (A) | Power | control box type | weight (kg) | ||

| GZ1 | 5 | 7 | 50 | 1.75 | 220 | 1.34 | 1 | 0.06 | XKZ5G2 | 73 |

| GZ2 | 10 | 14 | 50 | 3.0 | 2.3 | 0.15 | 146 | |||

| GZ3 | 25 | 35 | 75 | 4.58 | 3.8 | 0.2 | 217 | |||

| GZ4 | 50 | 70 | 100 | 8.4 | 7 | 0.45 | XKZ20G2 | 412 | ||

| GZ5 | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | 656 | |||

| GZ6 | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | XKZ20G3 | 1252 |

| GZ7 | 250 | 350 | 250 | 24.6 | 20 | 3 | XKZ100G3 | 1920 | ||

| GZ8 | 400 | 560 | 300 | 39.4 | 32 | 4 | 3040 | |||

| GZ9 | 600 | 840 | 350 | 47.6 | 38.6 | 5.5 | XKZ200G3 | 3750 | ||

| GZ10 | 750 | 1050 | 500 | 39×2 | 32×2 | 4×2 | XKZ200G3 | 6491 | ||

| GZ11 | 1000 | 1400 | 500 | 47.6×2 | 38.6×2 | 5.5×2 | 7680 | |||