Main effect of dewatering screen is dehydration,, desliming, remove media,Used for the washed-out sand of the Sand stone factory , Coal Sludge Recover of the coal separating plant, tailings discharging dryly of the concentrating mill and so on.

The tailing dry discharging slurry is concentrated to more than 60% concentration by means of a high efficiency cyclone,Evenly into the V type feed inlet screen,First, filter out a lot of liquid,Then subject to power source,The forced separation of liquid tailings forward movement,Control the formation of coarse filter layer for two times within the water filtration,Fine tailings from the water tension and sand mixed in the ball,Then cluster the tailings stripping coarse sand filter layer fast linear motion to the dry line,The mine water control in dry 10%- 15%,So as to achieve delivery, dry pile, transportation and other purposes.

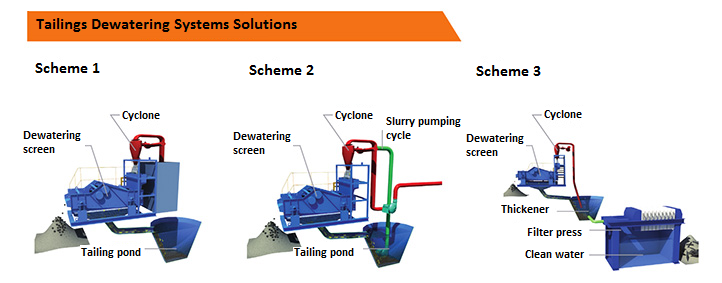

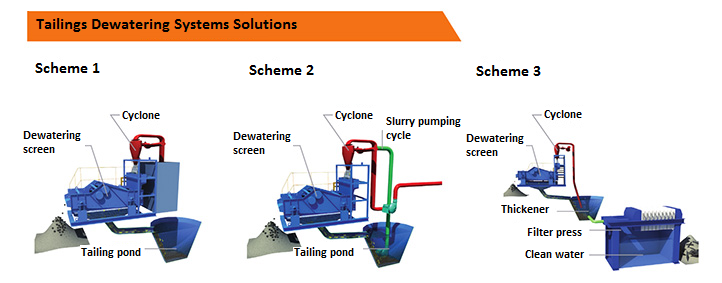

▶Scheme one

①Treatment process:The tailings slurry pump will be scored in the special cyclone tailings storehouse,After the concentration of the cyclone,the underflow discharged into the tailings dry line screen,the water content of the tailings is less than 15%,meet the requirements for dry reactor and transportation,dry overflow and underflow cyclone sieve discharged into the tailings,The scheme is less investment in equipment,small floor area,Simple process,easy to operate,can effectively reduce the flow into the tailings reservoir,the increase of tailings storage capacity and the service life,this scheme is the choice of most mineral processing plants.applicable to existing tailings to increase storage capacity.

▶Scheme two

②Treatment process:The tailings slurry pump will be scored in the special cyclone tailings storehouse,after the concentration of the cyclone,the underflow discharged into the tailings dry line screen,the water content of the tailings is less than 15%.Meet the requirements of dry heap and transportation.dry line screen underflow and overflow discharged into the tailings settling,the underflow then pump after precipitation of swirling flow is hit,such a system is formed in a closed circuit,It can effectively increase the service life of storage and tailings,needed for the project investment is small, less equipment, simple technology

▶Scheme three

③Treatment process:For slurry pump will be scored in the hydrocyclone tailings,cyclone underflow in dry tailings discharging screen,after the operation of the tailings,dry discharge of tailings in less than 15%,can achieve the dry heap and transportation of the requirements,after row of underflow and overflow of muddy water discharged into the dense pool and filter processing.the advantage of this process is that the tailings and water can be completely separated,water to achieve the effect of recycling,can completely replace the tailings.the scheme has a certain flexibility,all parts of the device can have a choice of use,press the relatively large energy consumption,dense pool after the material can be discharged to the previous cyclone and tailings dry sieve processing,this can also form a circular system.

The tailing dry discharging slurry is concentrated to more than 60% concentration by means of a high efficiency cyclone,Evenly into the V type feed inlet screen,First, filter out a lot of liquid,Then subject to power source,The forced separation of liquid tailings forward movement,Control the formation of coarse filter layer for two times within the water filtration,Fine tailings from the water tension and sand mixed in the ball,Then cluster the tailings stripping coarse sand filter layer fast linear motion to the dry line,The mine water control in dry 10%- 15%,So as to achieve delivery, dry pile, transportation and other purposes.

▶Scheme one

①Treatment process:The tailings slurry pump will be scored in the special cyclone tailings storehouse,After the concentration of the cyclone,the underflow discharged into the tailings dry line screen,the water content of the tailings is less than 15%,meet the requirements for dry reactor and transportation,dry overflow and underflow cyclone sieve discharged into the tailings,The scheme is less investment in equipment,small floor area,Simple process,easy to operate,can effectively reduce the flow into the tailings reservoir,the increase of tailings storage capacity and the service life,this scheme is the choice of most mineral processing plants.applicable to existing tailings to increase storage capacity.

▶Scheme two

②Treatment process:The tailings slurry pump will be scored in the special cyclone tailings storehouse,after the concentration of the cyclone,the underflow discharged into the tailings dry line screen,the water content of the tailings is less than 15%.Meet the requirements of dry heap and transportation.dry line screen underflow and overflow discharged into the tailings settling,the underflow then pump after precipitation of swirling flow is hit,such a system is formed in a closed circuit,It can effectively increase the service life of storage and tailings,needed for the project investment is small, less equipment, simple technology

▶Scheme three

③Treatment process:For slurry pump will be scored in the hydrocyclone tailings,cyclone underflow in dry tailings discharging screen,after the operation of the tailings,dry discharge of tailings in less than 15%,can achieve the dry heap and transportation of the requirements,after row of underflow and overflow of muddy water discharged into the dense pool and filter processing.the advantage of this process is that the tailings and water can be completely separated,water to achieve the effect of recycling,can completely replace the tailings.the scheme has a certain flexibility,all parts of the device can have a choice of use,press the relatively large energy consumption,dense pool after the material can be discharged to the previous cyclone and tailings dry sieve processing,this can also form a circular system.

| order number | name | unit | TS-12*31 | TS-14*31 | TS-18*37 | TS-24*48 |

| 1 | Feed concentration | % | ≥45 | ≥45 | ≥45 | ≥45 |

| 2 | handling capacity | t/h | 15-19 | 15-19 | 28-33 | 60-120 |

| 3 | Screen size | mm | 1200*3100 | 1400*3100 | 1800*3700 | 2400*4800 |

| 4 | mesh size | mm | 0.3,0.35 | 0.3,0.35 | 0.3,0.35 | 0.3,0.35 |

| 5 | double- amplitude | mm | 3-5 | 3-5 | 3-5 | 3-5 |

| 6 | Vibration frequency | Hz | 25 | 25 | 25 | 25 |

| 7 | outline dimension | mm | 3020*2400*2100 | 3020*2600*2100 | 3527*3060*2130 | 5025*3880*2693 |