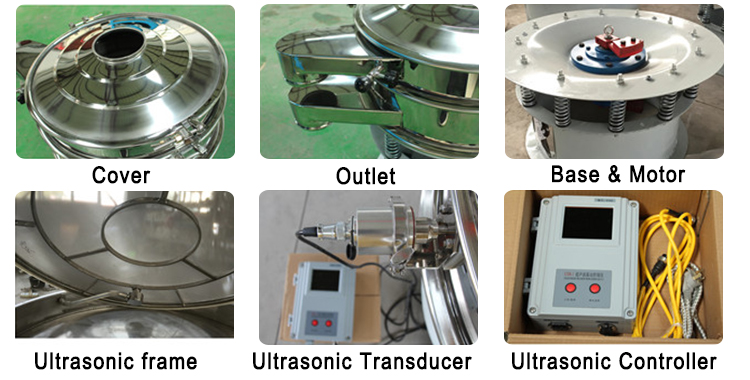

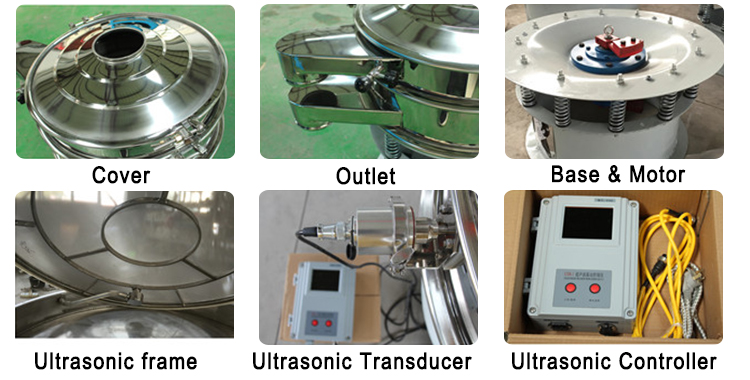

Ultrasonic vibrating screen machine is a new Powder Sieve Sifter For Filtration And Screening machine combining ultrasonic generator and round separator, in addition to three-dimensional round separator itself,Ultrasonic vibrating screen machine on the screen surface, which effectively solves the materials difficult to screen, such as: various high electrostatic, superfine, strong adsorption, easily aggregated, light relative density materials. Ultrasonic round separator not only avoids to block the screening mesh but also increases the screening capacity and accuracy, achieving the purpose of fast screening and cleaning.

Product show

.jpg)

.jpg)

.jpg)

Feature

1.It can be used with single or multilayer screen cloth.

2.Automatic dicharge of materials,continuous operation.

3.No dead corner of parts,easy rinse thoroughly and disinfection.

4.High screening precision,high efficiency,suitable for any power,grain and mucus materials.

5.New grid structure,long service life of screen cloth,only 3-5min for screen replacement.

6.Small volume,less space occupation,easy to move,360 degree adjustment of discharge opening.

7.Fully enclosed structure,no flying dust,no liquid leakage,no blocking of mesh opening,screen can reach 500 meshes,and filter can reach 5 um.

1.It can be used with single or multilayer screen cloth.

2.Automatic dicharge of materials,continuous operation.

3.No dead corner of parts,easy rinse thoroughly and disinfection.

4.High screening precision,high efficiency,suitable for any power,grain and mucus materials.

5.New grid structure,long service life of screen cloth,only 3-5min for screen replacement.

6.Small volume,less space occupation,easy to move,360 degree adjustment of discharge opening.

7.Fully enclosed structure,no flying dust,no liquid leakage,no blocking of mesh opening,screen can reach 500 meshes,and filter can reach 5 um.

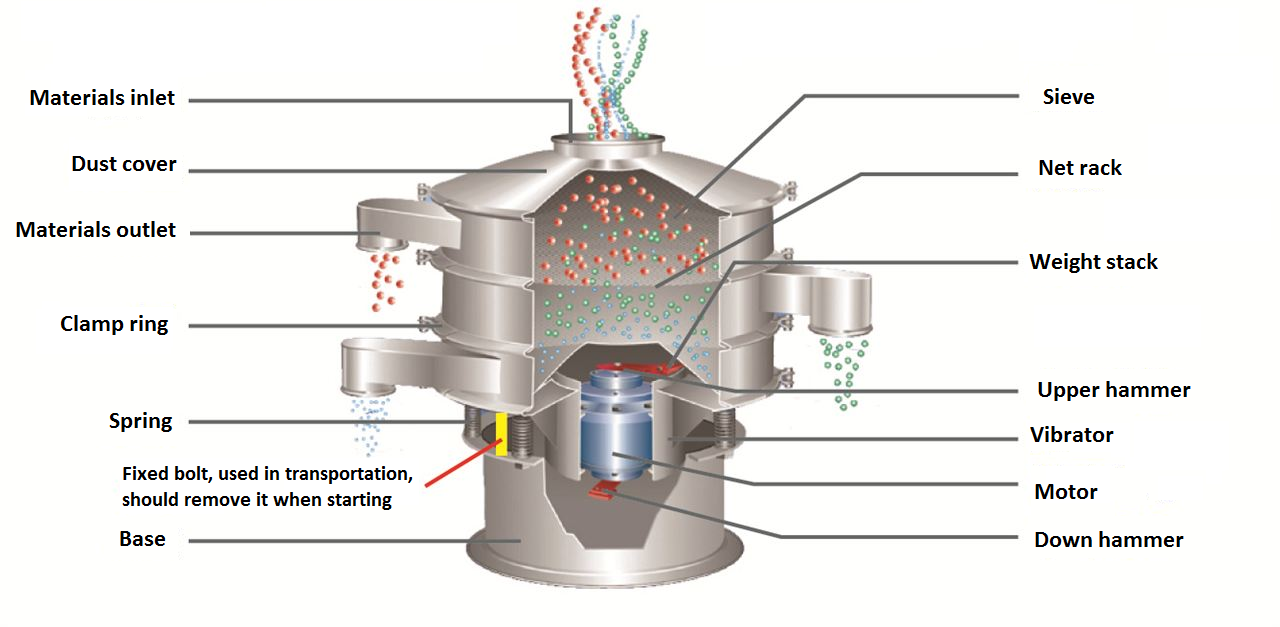

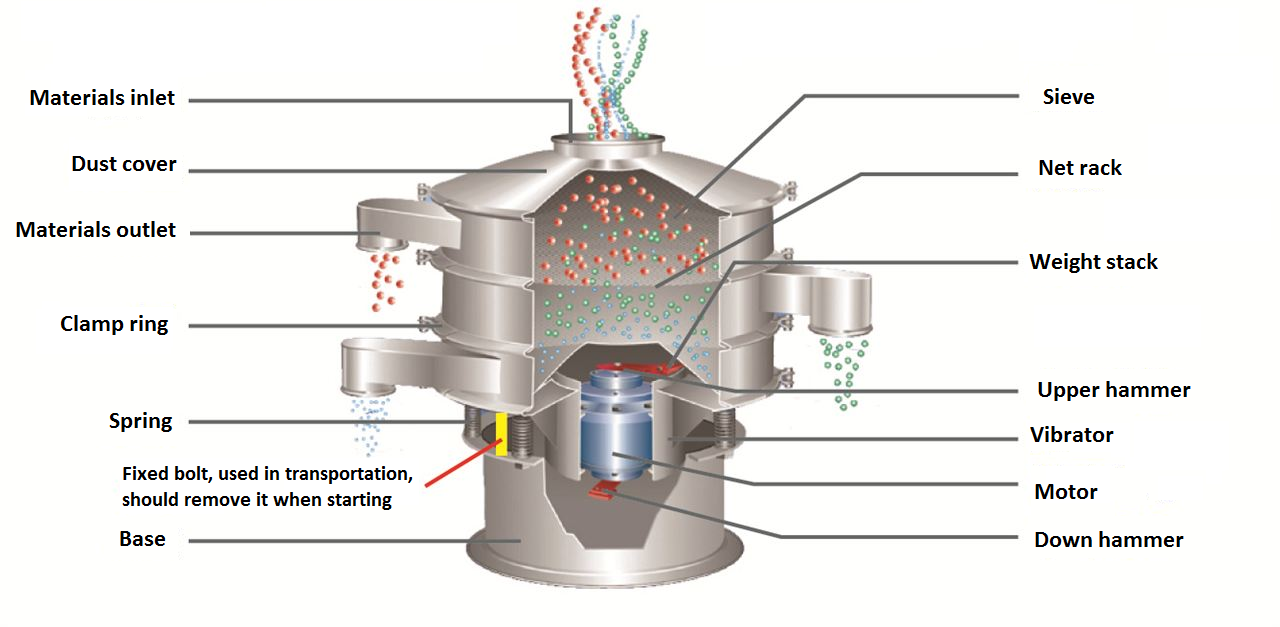

Working Principle

Rotary vibration screen is made of an upright motor as a source of vibration, the motor is installed at the upper and lower ends of the eccentric heavy hammer, the motor rotation motion into horizontal, vertical, oblique three-dimensional motion, and then the motion to the screen surface. Adjust the phase Angle of the upper and lower ends to change the motion track of the material on the screen surface.

The below table shows the detailed data of different models of Fine vibrator sieving metal powder ultrasonic vibrating screen machine for you reference, and we will choose a suitable model according to your specific materials and application.

| type | 400 | 600 | 800 | 1000 | 1200 |

| Effective screen diameter (mm) | Φ320 | Φ540 | Φ730 | Φ900 | Φ1100 |

| Effective screening area (m²) | 0.0804 | 0.2289 | 0.4183 | 0.6359 | 0.9499 |

| Screen specifications | 100~500 | ||||

| layer | 1-2 | 1-2 | 1-2 | 1-2 | 1-2 |

| Power(kw) | 0.18 | 0.37 | 0.55 | 0.75 | 1.1 |

Product show

Vibrating screen sieve is made of inlet,outlet,clamp,screen frame,screen mesh,vibrating motor,spring,

support base and so on.The below pictures will help you know more about our machine.

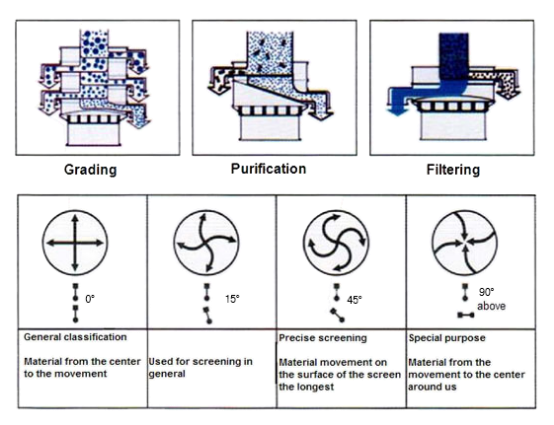

The following pictures show the different layers of Rotary Vibrating Screen.

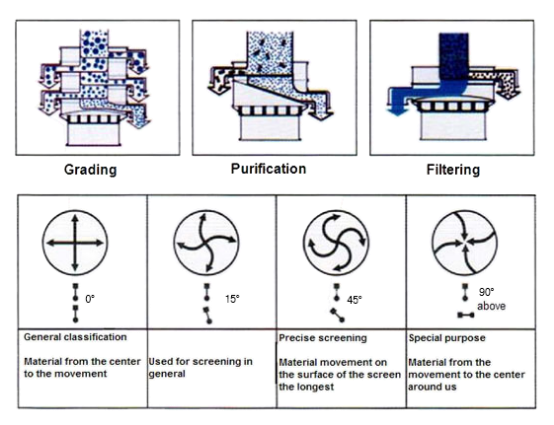

How does a vibrating screen work?

The vibration is accomplished by eccentric weights on the upper and lower ends of the motion-generator shaft. The direction of the eccentric weights can change its rotational mode,rotation of the upper weight creates vibration in the horizontal plane, which causes material to move across the screen cloth to the periphery,while the lower weight acts to tilt the machine, causing vibration in the vertical and tangential planes. The trajectories of materials on the screen can be changed by adjusting the phase angle of upper and lower weights.

The vibration is accomplished by eccentric weights on the upper and lower ends of the motion-generator shaft. The direction of the eccentric weights can change its rotational mode,rotation of the upper weight creates vibration in the horizontal plane, which causes material to move across the screen cloth to the periphery,while the lower weight acts to tilt the machine, causing vibration in the vertical and tangential planes. The trajectories of materials on the screen can be changed by adjusting the phase angle of upper and lower weights.

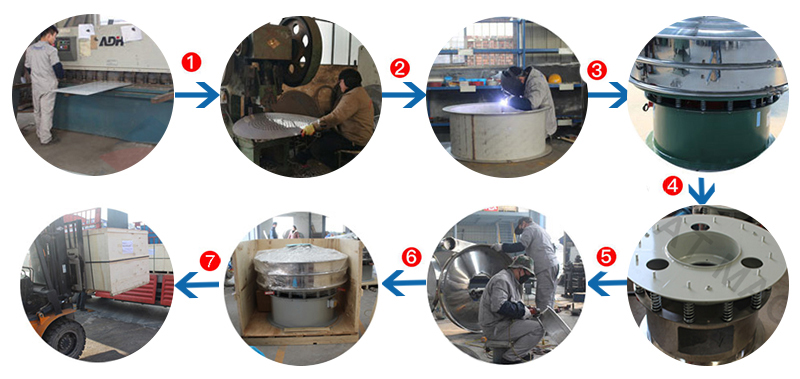

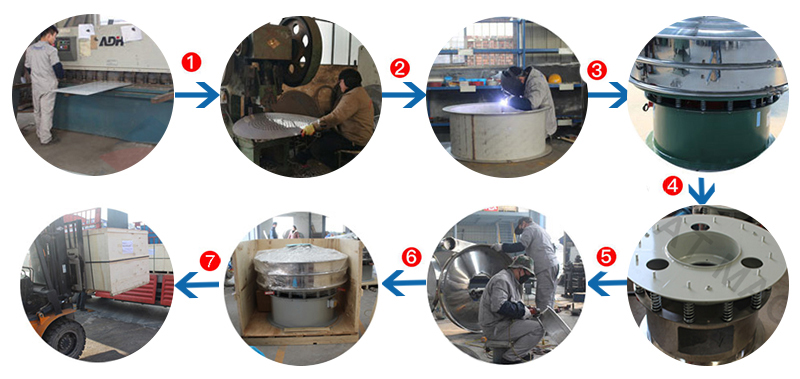

Rotary Vibrating Screen is designed by our engineers and produced by workers in our workshop. The following pictures show the procustion process for your reference.

Application

Ultrasonic vibrating screen machine is widely used in food industry, such as: grains, beans, mining industry, such as stone, coal,minieral, sand, chemical industry, such as coating powder, calcium carbonate, etc. Main functions are removing impurity,filtering, classification of material, solid-liquid separation, screening.

Ultrasonic vibrating screen machine is widely used in food industry, such as: grains, beans, mining industry, such as stone, coal,minieral, sand, chemical industry, such as coating powder, calcium carbonate, etc. Main functions are removing impurity,filtering, classification of material, solid-liquid separation, screening.

Company Information

Karat Machinery Equipment Co., Ltd is located in Xinxiang City--the hometown of China's vibrating screen. It is a professional manufacturer of screening and conveying equipment. Our company is specialty in the development and sales of vibration machinery, screening equipment, conveying equipment and lifting equipment. Our company produces a series of products as follows: rotary Vibrating Screen, screw conveyor, ultrasonic round separator, rectangular separator, vibration table, drum screen, standard laboratory inspection sieve, straight line vibrating screen, vibration motor, vibrating conveyor, feeding machine, hoisting equipment, belt conveyor. All of our production are widely used in food, pharmaceutical, chemical, metallurgy, building materials, mining, thermoelectric, environmental protection and other fields. And our company's business covers all parts of the country, and is exported to the United States, France, Canada, Russia, Australia, Japan, Singapore, Malaysia, India, Vietnam and other countries.

Karat Machinery Equipment Co., Ltd is located in Xinxiang City--the hometown of China's vibrating screen. It is a professional manufacturer of screening and conveying equipment. Our company is specialty in the development and sales of vibration machinery, screening equipment, conveying equipment and lifting equipment. Our company produces a series of products as follows: rotary Vibrating Screen, screw conveyor, ultrasonic round separator, rectangular separator, vibration table, drum screen, standard laboratory inspection sieve, straight line vibrating screen, vibration motor, vibrating conveyor, feeding machine, hoisting equipment, belt conveyor. All of our production are widely used in food, pharmaceutical, chemical, metallurgy, building materials, mining, thermoelectric, environmental protection and other fields. And our company's business covers all parts of the country, and is exported to the United States, France, Canada, Russia, Australia, Japan, Singapore, Malaysia, India, Vietnam and other countries.

.jpg)

.jpg)

Packaging & Shipping

Rotary Vibrating Screen is packed by wooden case or according to the customer's requirements.

Rotary Vibrating Screen is packed by wooden case or according to the customer's requirements.

.jpg)

Customer visit

We have many customers form all over the world and we have become very good friends in good communication.

We have many customers form all over the world and we have become very good friends in good communication.

FAQ

Q: What information do I need to provide for getting an accurate quotation for Rotary Vibrating Screen?

1. Material's name, bulk density, and water content

2. Capacity you required___kg/h

3. What's the purpose for our machine? Filtering, removing impurities or classification?

4. How many layers do you need?

5. The mesh size for each layer

6. Voltage and frequency

Q: How long for the delivery time?

A: 5-10 working days for conventional products.

Q: How long for warranty time?

A: 12 months from the shipping date.

Q: Can your engineer come to the construction site to guide the installation?

A: Yes, we can arrange our engineer to guide your installation, and salary is 150USD per day for one person, the air ticket/ visa/ local accommodation/ local traffic is in charge of customer

Q: What information do I need to provide for getting an accurate quotation for Rotary Vibrating Screen?

1. Material's name, bulk density, and water content

2. Capacity you required___kg/h

3. What's the purpose for our machine? Filtering, removing impurities or classification?

4. How many layers do you need?

5. The mesh size for each layer

6. Voltage and frequency

Q: How long for the delivery time?

A: 5-10 working days for conventional products.

Q: How long for warranty time?

A: 12 months from the shipping date.

Q: Can your engineer come to the construction site to guide the installation?

A: Yes, we can arrange our engineer to guide your installation, and salary is 150USD per day for one person, the air ticket/ visa/ local accommodation/ local traffic is in charge of customer

Generally there is no need to send our engineer to guide, because we will provide detailed installation drawings to the customer, the customer only need to find special installation team to execute.

Ultrasonic vibrating screen separator equipment can be up to 5 layers,and the mesh size can reach 500 mesh.We will choose a suitable model according to your specific materials and application.

| type | 400 | 600 | 800 | 1000 | 1200 |

| Effective screen diameter (mm) | Φ320 | Φ540 | Φ730 | Φ900 | Φ1100 |

| Effective screening area (m²) | 0.0804 | 0.2289 | 0.4183 | 0.6359 | 0.9499 |

| Screen specifications | 100~500 | ||||

| layer | 1-2 | 1-2 | 1-2 | 1-2 | 1-2 |

| Power(kw) | 0.18 | 0.37 | 0.55 | 0.75 | 1.1 |

Feature

1.It can be used with single or multilayer screen cloth.

2.Automatic dicharge of materials,continuous operation.

3.No dead corner of parts,easy rinse thoroughly and disinfection.

4.High screening precision,high efficiency,suitable for any power,grain and mucus materials.

5.New grid structure,long service life of screen cloth,only 3-5min for screen replacement.

6.Small volume,less space occupation,easy to move,360 degree adjustment of discharge opening.

7.Fully enclosed structure,no flying dust,no liquid leakage,no blocking of mesh opening,screen can reach 500 meshes,and filter can reach 5 um.

1.It can be used with single or multilayer screen cloth.

2.Automatic dicharge of materials,continuous operation.

3.No dead corner of parts,easy rinse thoroughly and disinfection.

4.High screening precision,high efficiency,suitable for any power,grain and mucus materials.

5.New grid structure,long service life of screen cloth,only 3-5min for screen replacement.

6.Small volume,less space occupation,easy to move,360 degree adjustment of discharge opening.

7.Fully enclosed structure,no flying dust,no liquid leakage,no blocking of mesh opening,screen can reach 500 meshes,and filter can reach 5 um.

.jpg)